Ultrasonic Plastic Welding Machine In Faridabad

Ultrasonic plastic welding is a sophisticated technology used to join plastic components by applying high-frequency ultrasonic vibrations. This process generates localized heat through mechanical energy, melting the surfaces of the plastic parts being joined. The result is a strong, permanent bond without the need for additional adhesives or fasteners.

How It Works

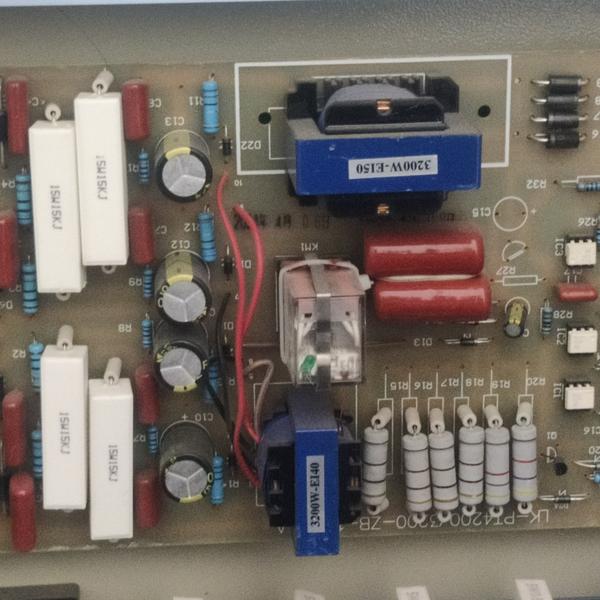

The ultrasonic plastic welding machine consists of several key components, including a power supply, ultrasonic generator, transducer, booster, and sonotrode (welding tip). The process begins when the generator converts electrical energy into high-frequency ultrasonic waves. These waves are transmitted through the transducer, which converts them into mechanical vibrations. The booster amplifies these vibrations, and the sonotrode focuses them onto the surfaces of the plastic parts.

When the vibrating sonotrode contacts the materials, friction generates heat, melting the plastic at the interface. Once sufficient temperature is achieved, the ultrasonic energy is stopped, allowing the melted surfaces to fuse as they cool. This method is particularly effective for thermoplastics, such as polypropylene, polyethylene, and polyvinyl chloride (PVC).

Advantages

Ultrasonic plastic welding offers several advantages over traditional welding methods. The process is quick, often requiring only a few seconds to complete a weld. It is also environmentally friendly, as it does not require adhesives or solvents. Additionally, ultrasonic welding can be automated, making it suitable for high-volume production lines.

Applications

Ultrasonic welding is widely used across various industries, including automotive, electronics, medical devices, and consumer goods. For instance, in the automotive sector, it is used to assemble components like dashboards and interior panels. In the medical field, ultrasonic welding is employed to create sterile packaging for medical devices, ensuring a secure seal that maintains product integrity.

In summary, ultrasonic plastic welding machines provide efficient, reliable, and environmentally friendly solutions for joining plastic parts, making them invaluable in many manufacturing applications.

Keywords

secure seal

welding tip

power supply

medical field

plastic parts

localized heat

consumer goods

interior panels

medical devices

automotive sector

product integrity

sterile packaging

electrical energy

mechanical energy

ultrasonic energy

various industries

several advantages

polyvinyl chloride

plastic components

ultrasonic welding

vibrating sonotrode

additional adhesives

ultrasonic generator

mechanical vibrations

sufficient temperature

several key components

strong, permanent bond

sophisticated technology

traditional welding methods

high-volume production lines

high-frequency ultrasonic waves

many manufacturing applications

environmentally friendly solutions

Ultrasonic Plastic Welding Machine

high-frequency ultrasonic vibrations